AC-SERVICES

Air conditioning, a modern marvel of technology, has revolutionized the way we live and work. It provides us with cool and comfortable indoor environments, making our lives more enjoyable during hot summer months. The concept of air conditioning dates back to ancient civilizations, where people used various methods to cool their homes. However, it was not until the early 20th century that air conditioning systems as we know them today were developed.

The invention of air conditioning has had a profound impact on society. It has made it possible for people to live in regions with extreme climates comfortably. It has also transformed industries such as manufacturing and agriculture by allowing for better control of temperature and humidity levels.

Moreover, air conditioning has improved public health by reducing the risk of heat-related illnesses and providing relief from allergies and respiratory problems. It has also enhanced productivity in workplaces by creating a more comfortable environment for employees.

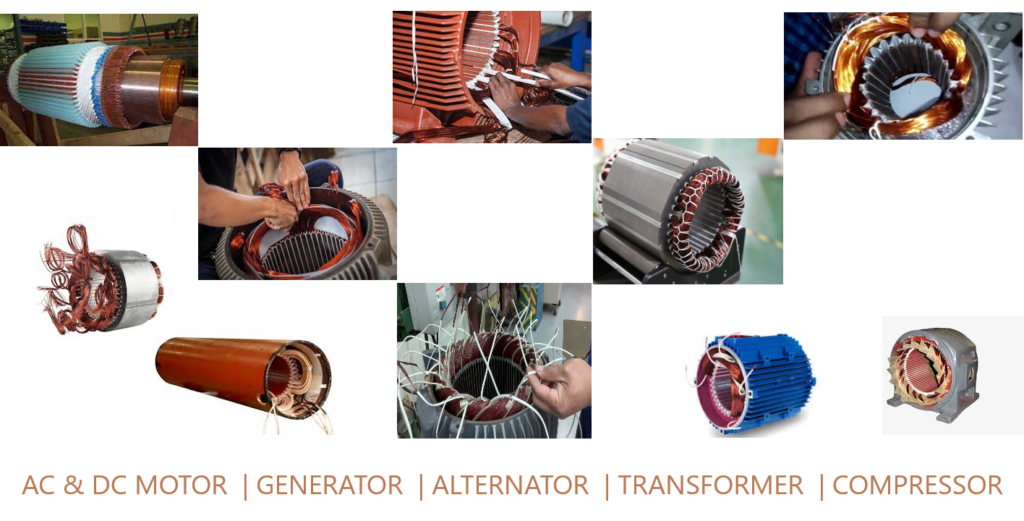

MOTOR / STATOR REWINDING

Motor rewinding is a crucial process in the field of electrical engineering. It involves repairing or replacing damaged coils in electric motors, ensuring their optimal performance and longevity. This practice dates back to the early days of electricity when motors were first invented.

The process of motor rewinding begins with the careful disassembly of the motor, exposing its internal components. The damaged coils are then identified and removed, making way for new ones. These coils are carefully wound around an iron core to create electromagnetic fields that generate motion.

Motor rewinding requires precision and expertise as even a minor error can lead to catastrophic consequences. Each coil must be wound with the correct number of turns and positioned accurately within the motor’s core. Additionally, the insulation between each coil must be carefully applied to prevent short circuits.

The benefits of motor rewinding are numerous. Firstly, it is a cost-effective solution compared to purchasing a new motor. Secondly, it allows for customization according to specific requirements, such as changing voltage or frequency ratings. Lastly, it promotes sustainability by reducing electronic waste.

In conclusion, motor rewinding is an essential practice that ensures the smooth functioning and extended lifespan of electric motors. Its historical significance cannot be overlooked as it has been instrumental in powering various industries for decades. As technology advances, so does our understanding of motor rewinding techniques – further enhancing its importance in today’s world.

SCREW COMPRESSOR

The screw compressor is a mechanical device that plays a crucial role in various industries, including manufacturing, oil and gas, and refrigeration. Its invention revolutionized the field of air compression and has become an indispensable tool for many applications.

The screw compressor operates on the principle of positive displacement. It consists of two interlocking rotors, known as male and female rotors, which rotate in opposite directions. As the rotors spin, the air or gas is trapped between them and compressed as it moves towards the discharge port. This continuous process ensures a steady flow of compressed air or gas with minimal pulsation.

One of the key advantages of screw compressors is their high efficiency. Unlike other types of compressors, such as reciprocating compressors, they do not require frequent start-stop cycles. This results in reduced energy consumption and increased productivity. Additionally, screw compressors are known for their low noise levels and smooth operation.

Another notable feature of screw compressors is their versatility. They can handle a wide range of operating conditions and deliver a consistent output even at varying loads. Moreover, they are highly reliable and require minimal maintenance compared to other compressor types.

In conclusion, the screw compressor has proven to be an invaluable asset in numerous industries due to its efficiency, reliability, and versatility. Its invention has significantly improved productivity while reducing energy consumption and maintenance costs. As technology continues to advance, we can expect further enhancements in this essential piece of machinery that will continue to shape various sectors for years to come.

PUMPS

Pumps have been an essential tool for centuries, serving various purposes in different fields. From ancient civilizations to modern times, pumps have played a crucial role in the development of societies.

One of the earliest known forms of pumps is the shadoof, which was used by ancient Egyptians to lift water from the Nile River for irrigation purposes. This simple yet effective device consisted of a long pole with a bucket attached at one end and a counterweight on the other. By pulling down on the pole, water could be lifted and transported to higher ground.

As technology advanced, so did pump designs. The invention of the steam engine in the 18th century revolutionized pumping systems. Steam-powered pumps were used extensively in mining operations to remove water from deep underground tunnels, allowing miners to access valuable minerals.

In modern times, pumps are used in various industries such as agriculture, manufacturing, and construction. They are employed for tasks like transferring liquids between containers, circulating fluids in machinery, and maintaining pressure in plumbing systems.

Furthermore, pumps have also found their place in medical applications. Devices such as insulin pumps help individuals manage their diabetes by delivering precise doses of insulin into their bodies.

In conclusion, pumps have been an integral part of human civilization throughout history. Their versatility and efficiency have made them indispensable tools across numerous industries. From ancient shadoofs to modern-day insulin pumps, these devices continue to play a vital role in our daily lives.

MOTOR

The invention of the motor is undoubtedly one of the most significant advancements in human history. From its humble beginnings as a simple machine that converted energy into motion, the motor has revolutionized countless industries and transformed the way we live.

The motor’s impact on transportation cannot be overstated. Prior to its invention, travel was limited to walking or relying on animal power. With the advent of the motor, vehicles such as cars, trains, and airplanes became possible. This not only made long-distance travel more accessible but also facilitated trade and communication between distant regions.

Moreover, motors have played a crucial role in industrialization. They have powered factories and machines, increasing productivity and enabling mass production on an unprecedented scale. The motor’s ability to generate consistent power has allowed for the creation of complex machinery that can perform tasks with precision and efficiency.

In addition to its practical applications, motors have also had a profound impact on society as a whole. They have provided new job opportunities and fueled economic growth. The availability of affordable transportation has brought people closer together, fostering cultural exchange and promoting globalization.

In conclusion, the motor is an innovation that has shaped our world in countless ways. Its influence can be seen in every aspect of modern life – from transportation to industry – making it an essential component of our technological progress. Without it, our society would be unrecognizable

SUPPLY OF REBUILD COMPRESSORS

The Rebuild Compressor Supply is an essential aspect of the industrial sector, providing a vital service to various industries. A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. It plays a crucial role in numerous applications, including refrigeration, air conditioning, and manufacturing processes.

Over time, compressors may experience wear and tear due to continuous usage. This can lead to decreased efficiency and even complete breakdowns. In such cases, rebuilding the compressor becomes necessary to restore its functionality.

Rebuilding a compressor involves disassembling it, inspecting each component for damage or wear, replacing faulty parts, and reassembling it with precision. This process requires skilled technicians who possess extensive knowledge of compressor systems.

The benefits of rebuilding compressors are manifold. Firstly, it is cost-effective compared to purchasing new compressors. Rebuilding allows businesses to save money while still maintaining optimal performance levels.

Secondly, rebuilding compressors promotes sustainability by reducing waste generation. Instead of disposing of old compressors in landfills, they can be refurbished and put back into operation.

Lastly, rebuilding compressors ensures uninterrupted production processes for industries that heavily rely on compressed air systems. By promptly addressing any issues with the compressor supply chain through rebuild

SUPPLY OF REBUILD CHILLERS

The chiller supply system is an essential component of any building’s HVAC system. It provides cool air to maintain a comfortable indoor environment, especially during hot summer months. However, over time, chiller supply systems can become outdated and inefficient, leading to increased energy consumption and higher operating costs. To address these issues, it is crucial to rebuild the chiller supply system.

One of the primary reasons for rebuilding the chiller supply system is to improve energy efficiency. Older systems often lack modern technology and are unable to meet the demands of today’s energy-efficient buildings. By upgrading the system with newer, more efficient components, such as variable speed drives and high-efficiency chillers, energy consumption can be significantly reduced.

Furthermore, rebuilding the chiller supply system allows for better control and monitoring capabilities. Advanced control systems enable operators to optimize performance based on real-time data analysis. This not only improves overall efficiency but also enhances comfort levels for building occupants.

Another benefit of rebuilding the chiller supply system is improved reliability and reduced maintenance costs. Aging equipment is prone to breakdowns and requires frequent repairs. By replacing outdated components with newer ones that have longer lifespans and require less maintenance, downtime can be minimized while reducing long-term operating expenses.

In conclusion, rebuilding the chiller supply system is crucial for improving energy efficiency, enhancing control capabilities, increasing reliability, and reducing maintenance costs. It ensures that buildings are equipped with state-of-the-art technology that meets current standards while providing optimal comfort for occupants. Investing in this upgrade will result in long-term savings and a more sustainable future for our built environment.